Our technology

- Home

- /

- Our technology

Maiken: Simple, Reliable, and Different

When Norwegian authorities introduced cost-free licenses for land-based salmon farming in 2017, many new and inexperienced players faced challenges in acquiring the technology needed for large-scale salmon production on land.

Arve Gravdal was surprised to see that most companies opted for standardized recirculating aquaculture systems (RAS). Based on his experience, he was convinced that this approach would not be viable.

This is where Maiken stands apart. Our technology is specifically designed to support industrial-scale salmon production on land.

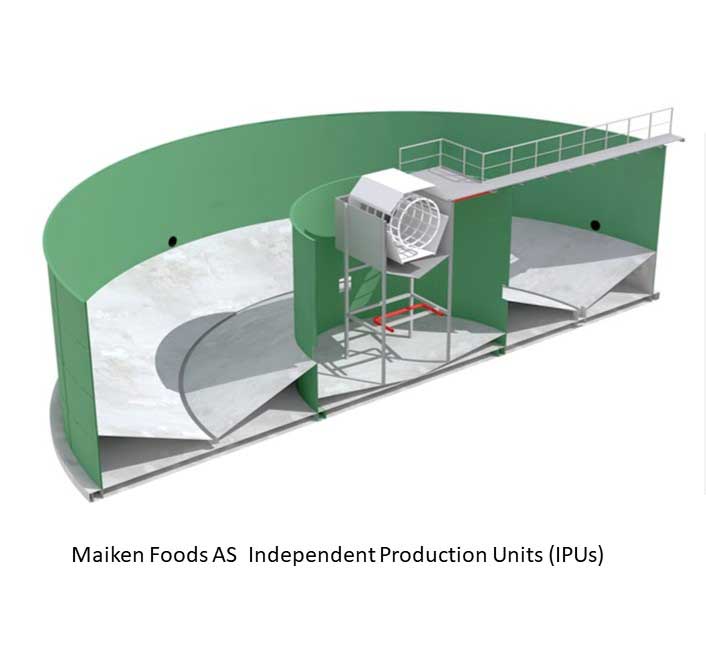

While many land-based fish farming companies have adopted centralized RAS systems, Gravdal and a group of industry experts have continued developing Maiken Foods AS’s Independent Production Units (IPUs)—a simple, reliable, and efficient alternative.

With Maiken’s system, juvenile salmon weighing 200-1200 grams are stocked in the tanks and harvested months later. The entire process is fully automated.

The cost-efficiency and economic feasibility of Maiken’s technology are highly favorable. We construct individual fish tanks with short build times, allowing us to begin production in the first tank while the next tanks are still under construction. This approach generates early cash flow, significantly reduces project risk, and provides exceptional flexibility in scaling and progress.

Growth Through the Use of Standardized Agricultural Tanks

- When Norwegian authorities introduced cost-free licenses for land-based salmon farming in 2017, many new and inexperienced players faced challenges in acquiring the technology needed for large-scale salmon production on land.

- Arve Gravdal was surprised to see that most companies opted for standardized recirculating aquaculture systems (RAS). Based on his experience, he was convinced that this approach would not be viable.

- This is where Maiken stands apart. Our technology is specifically designed to support industrial-scale salmon production on land.

- While many land-based fish farming companies have adopted centralized RAS systems, Gravdal and a group of industry experts have continued developing Maiken Foods AS’s Independent Production Units (IPUs)—a simple, reliable, and efficient alternative.

- With Maiken’s system, juvenile salmon weighing 200-1200 grams are stocked in the tanks and harvested months later. The entire process is fully automated.

- The cost-efficiency and economic feasibility of Maiken’s technology are highly favorable. We construct individual fish tanks with short build times, allowing us to begin production in the first tank while the next tanks are still under construction. This approach generates early cash flow, significantly reduces project risk, and provides exceptional flexibility in scaling and progress.

More on the technology...

IPU & DWTS: Key Advantages of Maiken’s Technology

IPU (Independent Production Unit) – With a construction time of weeks rather than months, technical features can be tested and adjusted before building the next tank.

DWTS (Dynamic Water Treatment System) – The unique and crucial technological anomaly of Maiken’s system is the DWTS:

In a traditional RAS, the ability to adjust flow and optimize the water treatment system during full operation is limited.

In contrast, Maiken’s system allows continuous adjustments to various water treatment processes.

The ability to adjust water flow and control the power/force of the water treatment system while in operation is critical.

As a result, Maiken can confidently claim that it will achieve an optimal production water environment for salmon within a reasonable period of operation—especially as more tanks come online.

Discharge water is thoroughly purified—removing sludge, nutrients, pathogens, and contaminants—before being released into the environment.