Our technology

- Home

- /

- Investors

Maiken Food AS. the game is changing!

Maiken is different - simple and reliable

When the Norwegian authorities in 2017 opened up for issuing cost-free land-based salmon licenses, it was challenging for the many new inexperienced players to obtain technology for producing large quantities of salmon on shore.

Arve Gravdal was surprised that most players chose a standardized recycling system. Based on his own experience he was convinced that this would not work.

This is where Maiken is different. Our technology is tailor-made for producing industrial quantities of salmon on land.

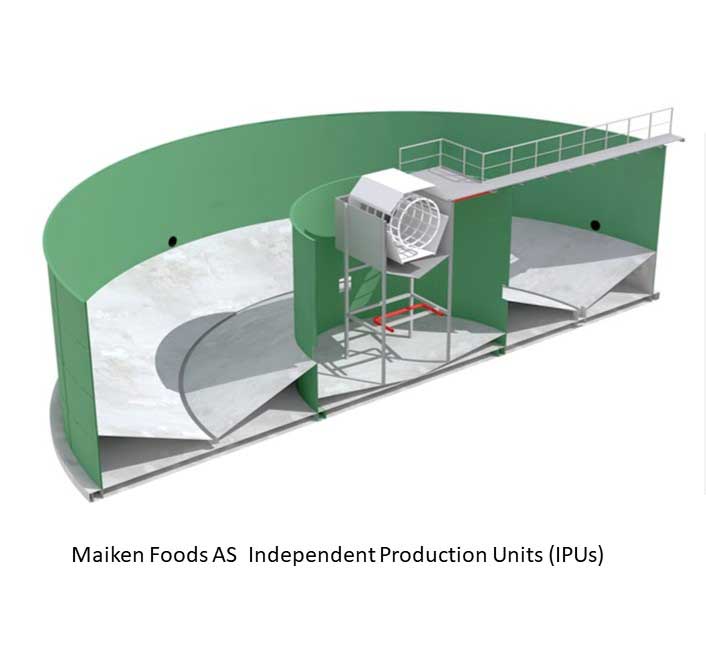

In parallel with the establishment – and continued establishment of land-based fish farming companies that use a standard centralized RAS, Gravdal and a number of other players have continued to work on the development of Maiken Foods AS – Independent Production Units (IPUs).

In our system, we simply stock the tank with 200 grams juveniles to harvest them 9 months later. Everything is automatic.

The cost and economy of the project with our technology appears to be very good. We build separate fish tanks with a short construction time, and we start production in the first tank before establishing the next one. This will allow us to achieve cash flow from the first production tank before the last tank is built. This contributes to a huge reduction in project risk and provides great flexibility on progress.

The technological solution - Independent Production Units (IPUs)

- Growth by use of standardized agricultural tanks.

- Several providers of tanks in various sizes, from 3m to 60m in diameter.

- Cost per tank of typically NOKm 25 for 34m.

- Rapid construction process of 1-3 weeks from material reaching site

- Maiken Foods AS to provide RAS and related technology

- Technology mostly based on off-the-shelf products used in a purpose built application, gradually developed over 10 years

- RAS required equipment is integrated in each tank, making the production 100% tank independent

- Growing tank size reduces CAPEX/kg significantly

- Already in 2002 an early stage of the technology was used to rear smolt to adult salmon of 2.8 kg in Norway

- Test facility in Ireland was built in 2010 and test gave proof of concept in complete control of environment

- Recent years the technology has been used in Scotland with success, with production intensity tested

Previous owner with focus on technology development not in position to raise capital for growth of farming facilities (one-time/non-recurring situations, mainly due to lack of liquidity resulted in stop of production)

More on the technology...

- IPU – With a construction time of weeks rather than months the technical features can be tested and adjusted before building the next tank.

- DWTS – Dynamic Water Treatment System. The unknown, but very important Maiken technology anomaly is the DWTS:

- A common RAS has limited options to adjust flow and optimize the different water treatment system whilst in full operation, whereas Maiken can adjust the different water treatment systems all the time.

- To be able to adjust the waterflow and to adjust the power/force of the different water treatment system whilst in operation, is of decisive importance.

- Thus, it is reasonable for Maiken to claim that it certainly will reach an optimal production water environment for salmon within a reasonable period of time of operation. Especially after several tanks are in operation.

- Discharge water, will be cleansed for sludge, nutrients, pathogens, and contaminants before letting the water into the recipient.